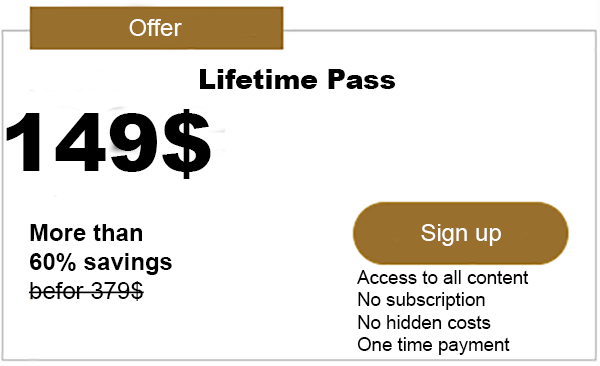

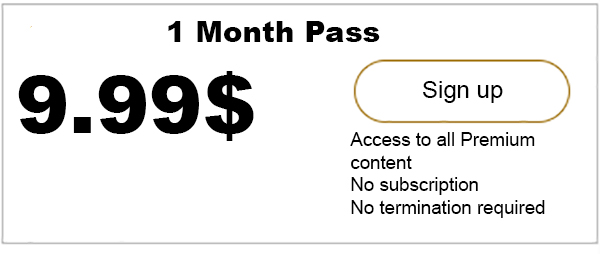

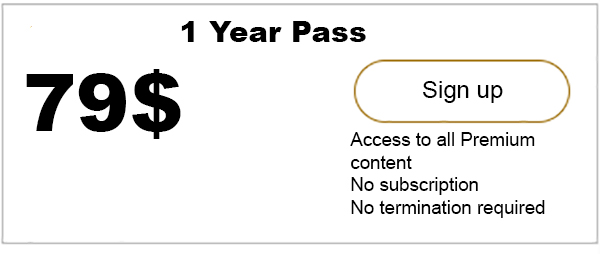

Advertisment

A company’s supply chain is a set of activities or operations involved in carrying out the process of selling a product in its entirety. These activities range from supervision, the process in which raw materials are obtained, the manufacture of products, production, distribution, transport and delivery of these. One of the objectives to achieve by…

iota-news.com is author of this content, TheBitcoinNews.com is is not responsible for the content of external sites.

Our Social Networks: Facebook Instagram Pinterest Reddit Telegram Twitter Youtube